How Robotics Can Help SMBS Automate for a Smarter Future

Tech advancements, lowering price points, and lingering skills gap are ushering in the next wave of robotics adoption.

The Evolution of Robotics in SMBs—from Hesitation to Innovation

Robotics offer the potential to automate mundane, repetitive tasks, which can help small and medium-sized businesses (SMBs) in manufacturing cut production costs and improve quality control, but these smaller companies have largely stayed on the sidelines, while bigger companies have reaped the benefits. Today, companies of all sizes can start benefiting from robotics. Read the white paper to learn how the time is right to start implementing robotics to help your business reduce costs, improve quality and do more with less people.

How Robotics Can Help You Build Your Workforce of the Future

The global manufacturing industry has been plagued by shortages of skilled talent caused by a number of factors. The impact of this shortage is costly. In the U.S. alone, the skills gap is costing the economy $13 billion a month. For SMBs, the problem is magnified, especially when these smaller businesses are located in rural areas with already shallow labor pools. Read this white paper to learn how adding robotics to your production can help you improve efficiencies and build your workforce of the future.

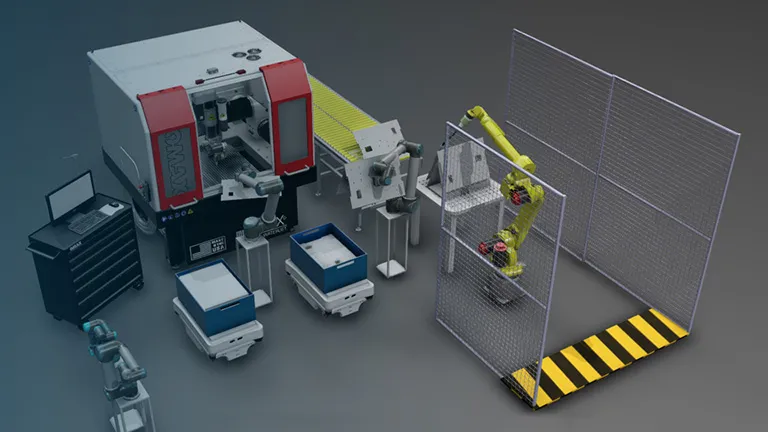

Robot Programming Academy

Learn how you can build, simulate, validate, and program industrial robot workcells in-house and under budget with Robot Programmer, a solution in the 3DEXPERIENCE® Works Manufacturing portfolio. Join Tony Karew, SOLIDWORKS® Robotics Expert, as he walks you through the lessons that will take you from workcell and plant layout, to device building and kinematics, to robot teaching and simulation, and onto validation and also offline programming.

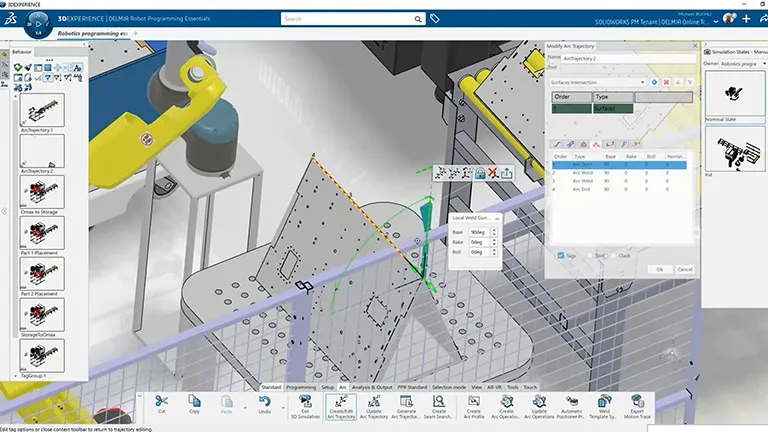

Industrial Robot Programming Simplified

Today, almost every robot comes with its proprietary robot programming language. This has been a long-standing issue in industrial robotics that has been exacerbated by the long delivery times for new robots. Companies are forced to mix and match brands based on availability. This results in manufacturing teams having to learn a new language every time they utilize a new robot brand within their facility. Watch this on-demand webinar to learn how Robot Programmer, a role in the 3DEXPERIENCE Works portfolio, simplifies the process by providing programmers with a comprehensive set of capabilities to help layout and program robotic systems more safely and efficiently.

Learn More About 3DEXPERIENCE Works Robotics Solutions

Ready to take the next step with 3DEXPERIENCE Works?

Ask a reseller about the benefits & cost of adding 3DEXPERIENCE Works to your current SOLIDWORKS investment.